Interview: Tend with Katie Troutman

Today's guest has created an inspiring soil-to-soil product & practice 🤎

“The amount of clothing we have on this planet right now could clothe our population for six generations, and more is being made every day,” Katie tells me.

While the world isn’t facing a clothing shortage, there’s an urgent need for innovation in textiles to tackle the mounting waste and microplastic contamination that most clothing contributes to at the end of its useful life. Additionally, as Katie points out, “if the materials our clothes are made of is bad for the environment, how is it impacting our bodies?”

Katie Troutman, founder of Tend—and our special guest this month—dreamed of creating a company that served women. She never could have predicted where that inner calling would lead her.

Coming from the tech industry, Katie's decision to follow the principles of nature contrasts sharply with the moonshot approaches of fast-paced startups. Today, we’ll explore the story of how Tend, a closed-loop clothing company, came to be.

INTERVIEW

Tell us a bit about your upbringing! Have you always been environmentally minded?

I grew up in southern California. While I would not have consciously identified as being environmentally minded, environmentalism was part of the fabric of life growing up. I have early memories of doing beach clean-ups with an organization called Surfrider. With those values instilled so young, I inherently cared for our waterways, it was second nature.

What’s your career journey been like?

Shortly after college I got a sales position for a local corporation and my career snowballed from there. From the start, I sold more technical products, which led into software sales. I worked my way up, as they say, and eventually led a national sales team. Right about that time, I’d had enough of the corporate life and chasing ever-growing sales quotas. Something deep down in me was exhausted. I think that is part of what motivated me to create an organization that served women and honored more natural rhythms.

I never pictured myself growing up to be an entrepreneur, it also just sort of “happened”. My early instincts were to become a designer, so that kind of flowed into my first entrepreneurial venture: making women’s underwear. Originally, I thought it would just be a side hustle but I loved it and wanted to make it my “main thing”.

Why women’s underwear?

I suspect part of what influenced my business idea was a trip I took to Australia - my bag with my underwear in it got lost in transit, so over the course of my travels I ended up accumulating more underwear than I’d probably ever owned at once. A few months later I started dreaming of creating a women’s underwear company.

I was also inspired by meditation; meditation changed my life. My original idea was to provide customers with a new pair of underwear every month with a mindful, centering mantra printed on every pair.

When and How did you get started on creating the business?

It was over ten years ago when I got started. To be honest, my first inclination was to buy a bunch of blank underwear through Alibaba and print on them. That seemed like a smart business decision – buy low, sell high, right?

Early on I was introduced to a consultant overseas who could help me develop my product. Starting that journey was really exciting, I felt like I got a crash-course in fashion design, sampling fabrics and developing different styles was a lot of fun!

When did you start becoming concerned with the environmental aspects of the clothing industry?

As I was developing the product I began asking about the origins of the materials and the various chemical treatments involved. I also had questions about biodegradability and recyclability but it was really difficult to get answers.

One reason it was challenging to trace these details was that, as a small brand working with low minimums, I had to go through a jobbers (someone who orders excess fabrics from various mills).

While the environmentalist in me started to awaken, I was on the verge of launching a business and felt pressure to get a product into customers hands. At the time, I felt I needed to move quickly, do my best with what I had, and figure out the rest later. I mostly ignored the concerns I had about the materials and kept moving forward. Looking back, that was when the seeds of what would become fundamental values for Tend were planted.

What happened with the business?

We continued for a couple of years, but ultimately, it wasn’t profitable. I had to maintain other jobs, and eventually, I decided to shelve the company.

Still, I loved the experience! I promised myself that if I ever became independently wealthy, I’d try it again. I kept up with developments in sustainable fashion, which started gaining attention around 2014.

When did you pick the idea back up again?

It wasn’t until 2020 that I experienced a significant shift. Like many, it was a strange time that offered a pause in my life. Beyond the pandemic, I was turning 40, and my mother was ill, so I went to Montana to be with her. This turned into a period of deep reflection.

I thought, even if it takes forever, why not focus on what I truly care about? I removed the pressure of turning it into a business and that mindset shift reopened the idea for me. I decided that I would only pursue this if it redefined how underwear functioned in our lives.

What do you mean by redefining underwear?

Many fashion companies are merely brands — mostly names and images. I didn’t want that. Instead, I wanted to take a systems thinking approach. So, I committed myself to thorough research and quickly realized we have a materials problem preventing a healthy life-cycle for undergarments.

Tell us more about your research into materials.

I spent nearly two years researching materials and their history - there were many rabbit holes! Caroline Cockerham was a great resource for me.

In short, many synthetic materials trace their origins to wartime technology. For instance, polyurethane was developed as a rubber alternative to support the war effort. DuPont then used this technology to create Lycra which, interestingly enough, was first used in women’s underwear, primarily girdles.

Today, upwards of 80% of our clothes contain elastane. I like to point out that elastane has its benefits—it moves well and accommodates our bodies as they inevitably change. So, there are both pros and cons.

Tell us more about elastane. What can be done with products containing elastane once they've reached the end of their useful life?

Elastane gives our clothes “recoverable stretch” and we’ve come to expect that characteristic in a lot of clothing, especially underwear. Elastane isn’t recyclable or biodegradable, at least not in any reasonable timescale. It is also sourced from petrochemicals. There are a few sources for petro alternatives but chemically they are the same environmental problem, just a different carbon source.

How have you gone about the challenge of making a product without elastane?

Upon realizing the environmental downsides of elastane, I focused on researching bio-based materials. I was inspired by Biomimicry Institute. Ultimately, it became clear that there’s a materials gap.

At some point I was like, “Am I going to end up making an underwear company or become a materials science company?” Honestly, getting farther down the road was a bit of a bummer – being a material science company is way different than making underwear and managing a clothing brand!

Are there any examples of material science companies in the fiber industry?

Pangaia is at the forefront of material science in textiles. I think we’ll see more initiatives like theirs, I’m anticipating a materials revolution!

Patagonia also has an in-house materials lab and a lot of investment in materials, they are a great resource!

It’s interesting how the war time technology was focused on “how do we make this last forever” and the current revolution is rethinking how that’s working for us as we’re dealing with “forever chemicals” and waste that won’t breakdown!

Exactly, the objective is entirely different now. We want to make durable products but in a way that nature can not only safely digest but actually benefit from.

After your deep dive into materials research, what came next for you?

When I shifted my focus to biomimicry and materials design, I learned about fibersheds. Finding Fibershed (the organization) was a pivotal moment for me. From their mission to how they were structured inspired me in so many ways – the local-sourcing, and open-source model / sharing of information - it reshaped my idea of what success could look like.

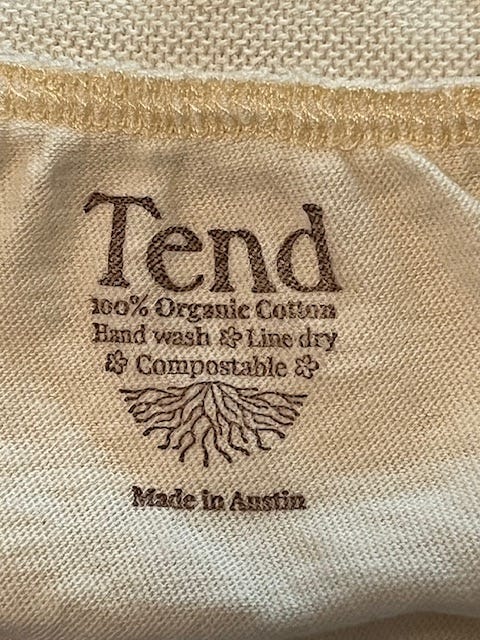

By this point in my journey, I was designing for a compostable end of life. Fibershed’s Soil-to-Soil model was exactly how I wanted my garments made.

With Fibershed as an anchor point and compostability as a beacon, something in me just told me to follow that path, to follow nature. I realized that in order to make the product I want to make, it needs a fibershed and it needs to be compostable.

The current concept of Tend was born from these insights, it became my mini version of the 150-mile challenge.

How did you come to the business name, Tend?

I have a teacher who talks about tending our lives like we do our gardens, and that idea resonated deeply with me, especially being a compostable clothing brand. This concept guides our design ethos — from how materials are grown, sourced, and made, to how they can be used and eventually returned to the soil.

I also chose it because it’s a verb, I see Tend as a practice, not a consumable.

Once you had a new sense of direction, how did you start developing Tend?

Well, there wasn’t a Texas Fibershed so I thought, I guess I’ll start one. Then I set out on my challenge to source materials and processors.

Were you able to make all-natural underwear sourced entirely in Texas?

Unfortunately not! We use Texas grown organic cotton, it’s been milled and turned into fabric in North Carolina. I have a specialty elastic chosen for its compostability that I source in Europe.

Overall, the materials to make a pair of Tend, travel 25,000 miles to be cut and sewn here in Texas! Nonetheless, that’s about half the mileage of an average garment today.

In 2023 I was telling my friend how I found all my sources for materials that would compost, but it’s still not perfect, the journey is way longer than I’d hoped. But she encouraged me to make the product anyway and start sharing about it. So, that’s what I’ve been doing in the last year, all while working a full time job.

What has proved to be the most challenging part of designing or making the underwear?

Aside from not using any elastane in our fabrics, the elastic is still difficult in terms of the “soil to soil” model. I don’t want to say that elastic is necessary as I like the fun challenge of figuring out other ways to design underwear, but using elastic at least for the waist band, seems to make sense. I had a contact in Berlin who I knew had done studies to show their elastic was compostable - it’s made from rubber trees grown in Malaysia. So, it’s natural but it must be vulcanized to create a durable, recoverable stretch and that process is what disrupts “mother nature's way” you might say.

Also, figuring out how to go about selling the product has been challenging. With the materials journey already being so long, to then sell a product to someone in Miami or London and the extra mileage for that… I’m not sure if that’s how we want to go about it. I love the idea of sourcing, making & selling within bioregions as much as possible.

Tell us about the compostability part – how’d you settle on composting instead of something like a take-back / recycling program?

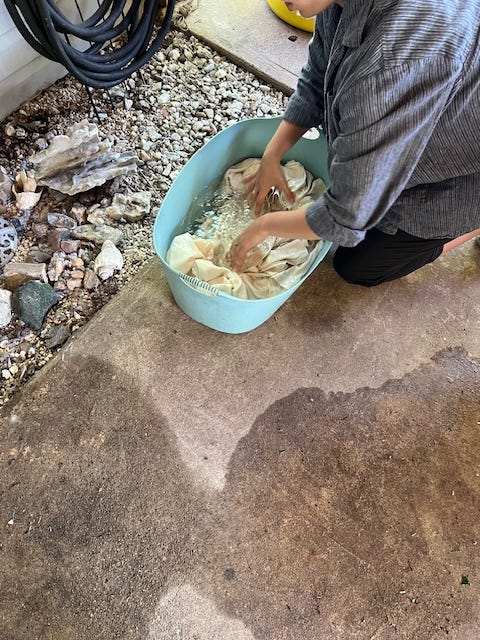

For one, there’s a lot of infrastructure needed for take-back including more mileage/shipping. I love the backyard composting as a systems solution. Composting in that casual setting is the gold standard in my opinion, not industrial composting.

I realize not everyone has access to a compost pile or even municipal composting. Knowing our garments can compost, that is something I want to wear on my body. Especially a product as intimate as underwear. In my mind, choosing our clothing is similar to what foods we choose to eat because how they impact the environment, they also impact our bodies.

I chose “Tend” because it’s a verb. I see Tend as a practice, not a consumable.

-Katie Troutman, Tend

What’s next for Tend?

I mostly feel pulled to do more research with ongoing small batch releases of product. Lately I’ve been thinking on how to fund the research.

Since Tend undies are about so much more than a product, it’s important to me that anyone who owns a pair not only understands the story and purpose, but that they feel equipped to compost the garments at home once they’re at the end of their useful life. So, I thought hosting educational workshops might be the best place to start selling the product.

What has the latest research looked like?

Most recently we’ve been doing compost trials, which you’ve helped with! If we can find funding for it I’d love to investigate the forensic blueprint of the materials. I’ve been pulling on the threads of metabolic ecology and believe that’s where we will focus.

ADVICE

What advice do you have for those of us looking to improve the footprint of our wardrobes?

Similar to shopping food products, read the label and don’t be afraid to ask questions. The companies who are doing the real work are showing the work and not just making claims / greenwashing.

Linked at the end are sources for soil to soil apparel!

Do you have any advice for someone who is pursuing an interest while holding down a job?

Oh, man. I wish I had more answers, I’m still trying to figure out the economics of my own life and this project. I’d say that it’s important to be honest with yourself about how you’re going to finance your lifestyle, while also pursuing an interest or cause that’s important to you. For me right now it still feels important to not put financial pressure on Tend.

You’ve put a lot into Tend, how has it given back to you, why do you keep going?

When I was feeling depressed about the lack of materials and solutions in the clothing industry, it helped so much to just work on the problem.

I’ve found, and I see you do this too, that getting involved in my community is hugely helpful to my sense of connection and purpose. In my experience, taking what action you can, even if that’s just tinkering around or going to relevant workshops, is a constructive way to cope with big complex problems.

Anything else you’d like anyone reading to know?

I believe we were born in this time because our contributions are needed to make for a healthier, more vital world. We talked about how so many materials originated for wartime purposes… imagine if we created from a place of love instead of fear.

And it’s not about labeling anything as “bad” – what’s done is done. But now that we understand the implications of past decisions, it’s our responsibility to address them.

Could not agree more. 💫

Resources

Check the Tend website to stay informed on small batch releases & workshops

Instagram: @togetherwetend

Soil to Soil Directory / IG: https://www.instagram.com/soiltosoildirectory/

Compost Clothes / IG: https://www.instagram.com/compostclothes/

California Cloth Foundry / https://www.instagram.com/caclothfoundry/

Alabama Chanin / IG: https://www.instagram.com/alabamachanin/?hl=en

Other Compostable Underwear brands: Kent, Pansy, The Very Good Bra

This interview was edited and condensed for clarity. Photos and proofreading provided by Katie Troutman.

I believe we were born in this time because our contributions are need to make for a healthier, more vital world.

-Katie Troutman, Tend

Please help me thank Katie for her work in the world and for sharing it with us!

This is an approach I have come to value and Katie's attitude and quest totally resonate with me. As a 70 year old who is the same body size as when I was 17, I have a 6 decade wardrobe of "forever clothes". I maintain I do not need to buy another garment, even if I live to 100, particularly if it does not honour seed to soil fabric and fabrication.