Field Notes: Compost Extract at Swift River Pecans

Take a look at the future of farming!

I recently had the chance to take my microscope on a field trip to Swift River Pecans with Troy Swift. Troy was generous enough to walk me through his entire compost extract process, step by step, while I got to peek at the biology under the scope at every stage. It was part insight gathering and part skillshare (which included a tractor-driving lesson!). Today, I’m sharing my notes and photos with you. This is the future of farming, y’all!

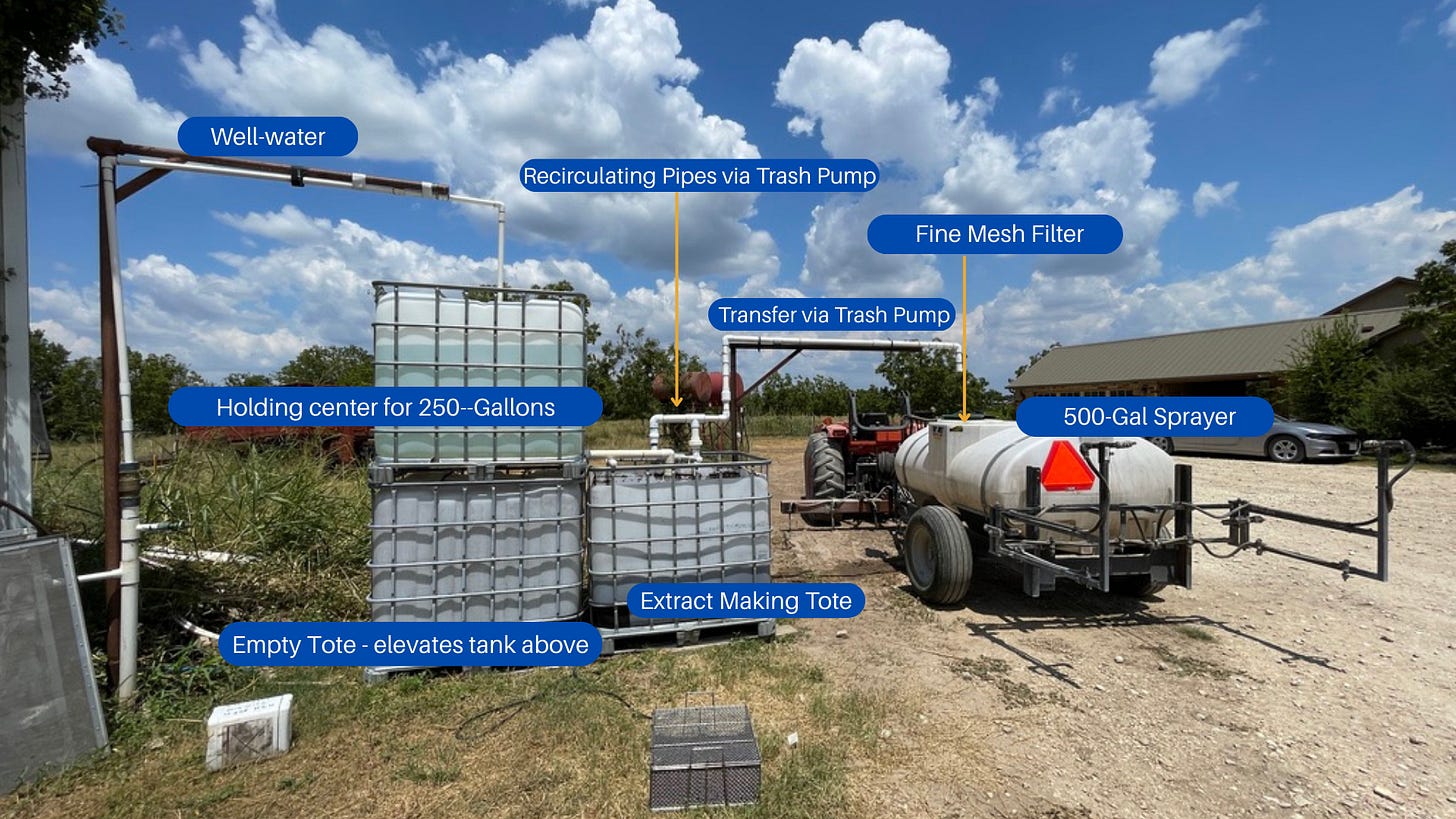

System Setup

Water supply: One IBC tote is stacked on top of another and filled with well water. The top tote gravity-feeds 250 gallons into a side tote where the compost extraction happens.

Pump: A submersible trash pump is used both for recirculation and for transferring extract to the spray tank.

Spray tank: Final volume brought up to 500 gallons in a field sprayer.

Extraction Process

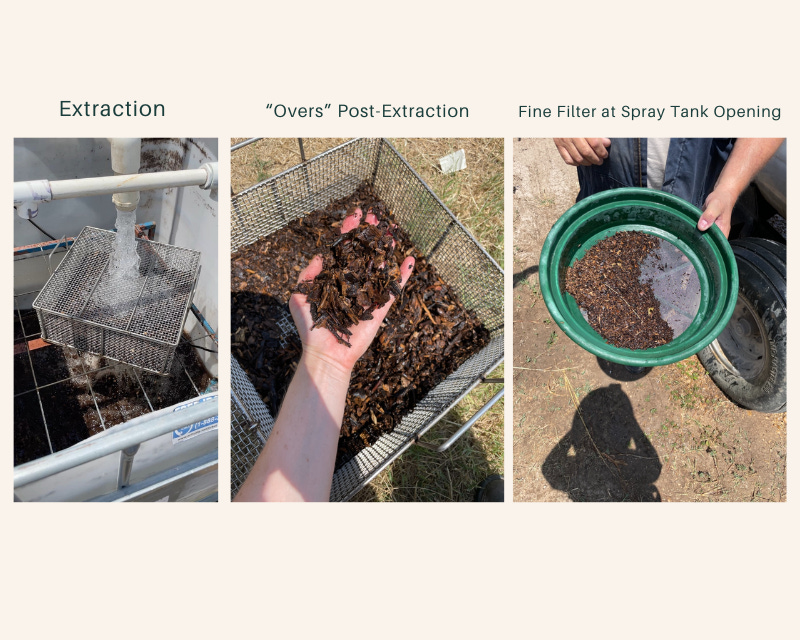

Compost loading: ~10 lbs of Johnson-Su compost was placed into a stainless steel wire cleaning basket.

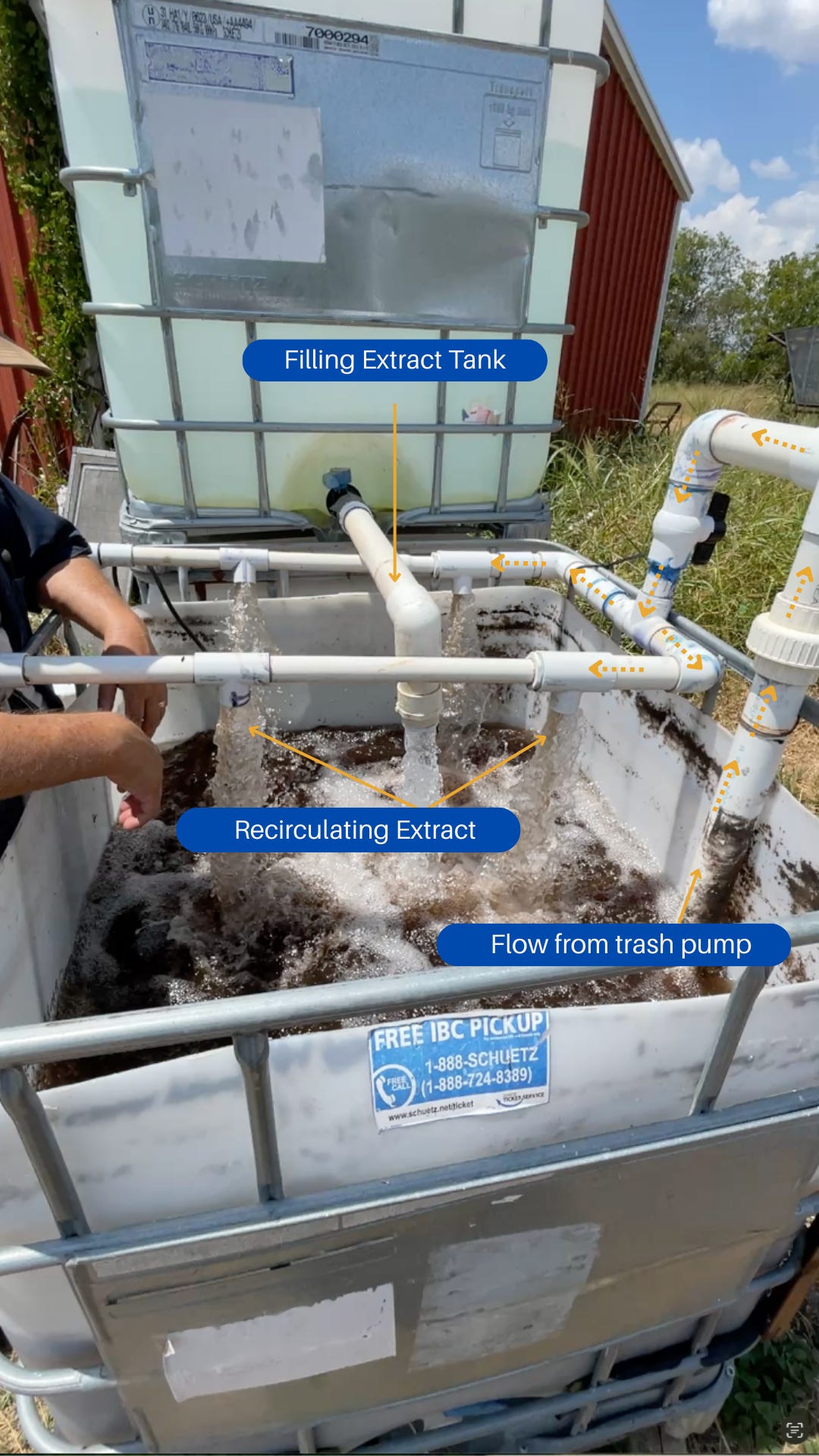

Breakdown: Within seconds of water flowing through, most compost dispersed into suspension, leaving only some woodchip remnants (pictured).

Recirculation: The trash pump ran to keep compost in suspension as the tote filled to ~250 gallons.

Transfer: A valve on the PVC plumbing diverted flow to fill the 500-gallon sprayer. A fine-mesh filter at the sprayer opening caught any stray wood chips (pictured).

Sampling & Observations

At each stage I collected samples to check biology:

Starter compost

Extract (10 lbs : 250 gal) directly from extraction tote

Recirculating extract in extraction tote

Diluted extract (10 lbs : 500 gal) in sprayer

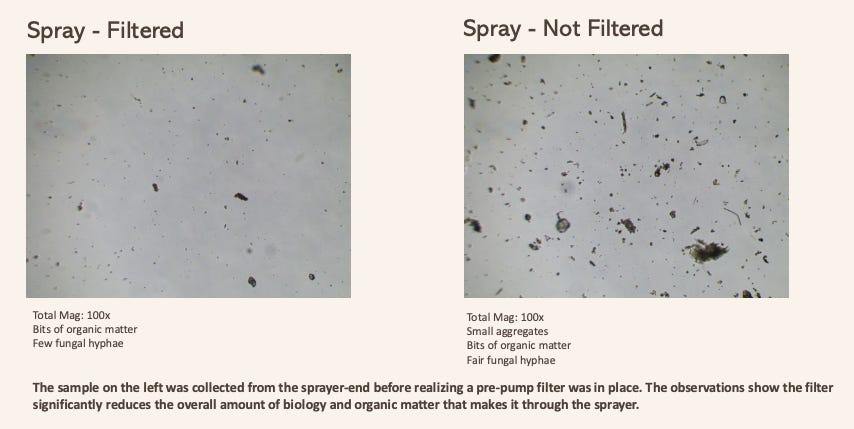

Extract from spray heads (filtered vs. unfiltered)

Extract sprayed at different pressures (40 psi vs. 60 psi)

An unexpected but useful learning moment came when Troy noticed a filter was still installed before the centrifugal pump on the sprayer. This is typically not in place when he applies extracts, but it gave us a chance to compare filtered vs. unfiltered spray — a significant difference under the microscope.

Outside of this filtered sample, I didn’t have any concerns about the pumps, plumbing, or sprayers harming the biology. Living aerobic microbes showed up in every sample, and I saw no evidence of problematic biofilms. The only questions left to consider were about good cleaning practices to maintain these conditions and whether it might be worth increasing the compost-to-water ratio to boost microbial density.

Application

The trailer sprayer (standard agricultural sprayer) required no major modifications other than removing filters at each nozzle and pre-pump. In addition to the fan nozzles at the back, the shanks provided light soil disturbance with drip-style nozzles that applied extract directly to the soil surface. Spray pressure was kept between 40–60 psi.

Tractor Lesson

Once the sampling was done, it was time to apply the extract in the orchard. Troy hopped on the tractor to give me a crash course.

“Have you ever driven a manual car?” -Troy

“…Does an ATV count?” -Me 😬

Needless to say, Troy was patient, and I tried to be a quick learner. I got in a couple passes before an unexpected (but much-welcomed) storm rolled in. We took cover in the barn, grateful the extract would be watered in with a proper rain.

Concluding Thoughts

Experiences like these mean a lot — they help me better understand the realities land managers face at a scale I don’t work on every day. It’s a gift to be invited into the field, bridging the gap between microscope work and real-world applications.

It also reminds me that whether we’re stewarding a backyard plot or hundreds of acres, we already have tools within reach to regenerate land.

Next on my experience wish list: seeing how a drone sprayer could be used to spread microbes. 🧐

PS: I hope my best friend from high school is reading and impressed with how many times I can now say the word nozzle with a straight face ;)

About Swift River Pecans

Troy Swift stewards 266 combined pecan acres along the San Marcos River. He is the President of the Texas Pecan Growers Association (TPGA). His orchard is the site of various ongoing research studies with collaborators such as Noble Research Institute, Texas A&M University, Texas State University and Merlin Tuttle’s Bat Conservation.

Swift River Pecans is a state champion in commercial pecans (2018, 2022). You can visit their store and tour their sawmill at 9975 San Marcos Hwy Lockhart, TX 78644 or purchase their responsibly made goods in-store or from their online shop.

I personally love using Swift River Pecan Oil in place of highly refined canola or grapeseed oil as it has a high smoke point! -Andie

🌱 Ways to Connect Further

Share Your Thoughts – take the reader survey or suggest a future topic

Book a Consult – one-on-one support for composting endeavors

Biological Assessments – we evaluate soils, compost, and amendments under the microscope at Rhizos LLC

Browse the Archive – posts are sorted into guides, soil, compost, deep dives and philosophy

Great article and project sharing. It’s interesting to hear how many steps are involved to assess microorganisms. Instead of sampling starter compost and nozzle end product, the other data points tell a key part of the story.

I am curious to hear a follow up about the benefits on the farm and the pesticides that might no longer be needed.